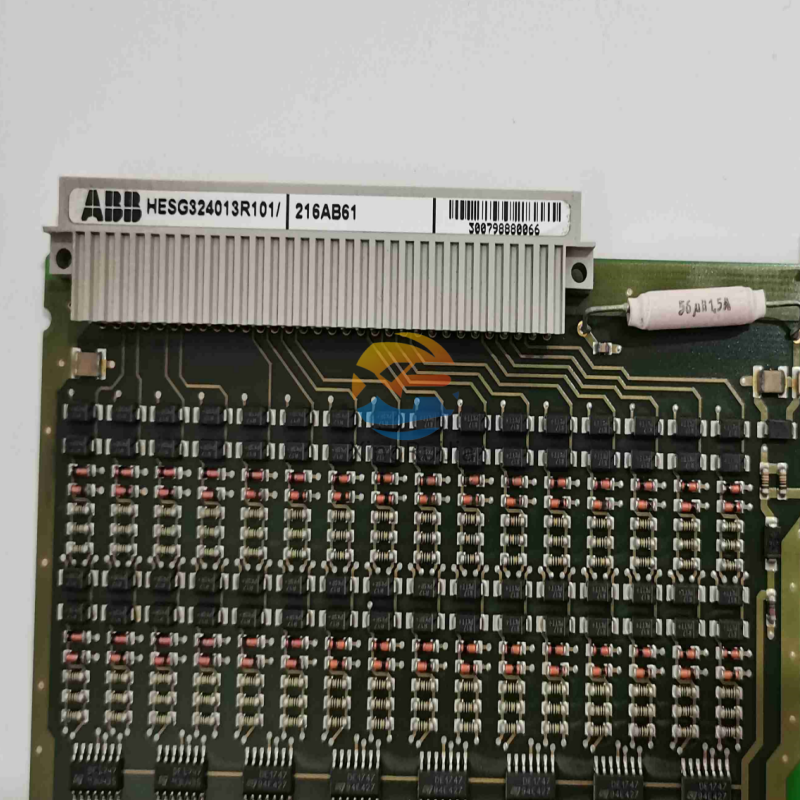

ABB PPD539A102 3BHE039770R01 AC 800PEC Central Processing Unit (CPU) - Complete Technical Profile

Executive Summary: The Heart of Advanced Process Control

The

ABB PPD539A102 3BHE039770R01 AC 800PEC Central Processing Unit represents the pinnacle of ABB's process automation technology, delivering unparalleled reliability, security, and processing power for mission-critical industrial applications. As part of ABB's renowned AC 800PEC (Process Edge Controller) series, this CPU module is engineered specifically for large-scale process industries requiring the highest levels of safety, availability, and cybersecurity. With the designation 3BHE039770R01, this particular model incorporates specific firmware and hardware configurations optimized for complex process control scenarios in sectors such as oil and gas, power generation, chemical processing, and pharmaceutical manufacturing.

Technical Specifications: Precision Engineering for Industrial Excellence

Processing Architecture & Performance

- **Processor Configuration**: Dual-core/multi-core processor architecture with hardware-based redundancy support

- **Clock Speed**: High-performance processing core with optimized real-time capabilities

- **Memory Capacity**:

- Flash Memory: 2GB minimum for program storage

- RAM: 1GB minimum with error correction code (ECC) protection

- Battery-backed memory for critical configuration retention

- **Processing Speed**: Sub-millisecond deterministic scan cycles for time-critical applications

- **Task Handling**: Support for up to 500,000 digital I/O points and 100,000 analog I/O points

- **Execution Performance**: Capable of executing over 500,000 function blocks per second

Redundancy & Reliability Features

- **Hot Standby Redundancy**: Seamless switchover with zero process interruption

- **Memory Synchronization**: Real-time data synchronization between primary and backup CPUs

- **Fault Detection**: Comprehensive self-diagnostic capabilities with predictive maintenance indicators

- **MTBF (Mean Time Between Failures)**: > 300,000 hours under standard operating conditions

- **Safety Integrity Level**: Support for SIL 2/SIL 3 applications when configured appropriately

Physical Specifications

- **Dimensions**: Standard 6U x 160mm x 220mm form factor

- **Weight**: Approximately 850g (1.87 lbs)

- **Power Consumption**: 24V DC nominal (range: 19.2V - 30V DC), typically 8-12W

- **Operating Temperature**: -40°C to +70°C (-40°F to +158°F)

- **Storage Temperature**: -40°C to +85°C

- **Relative Humidity**: 5% to 95% non-condensing

- **Shock and Vibration**: Compliant with IEC 60068-2-6 (vibration) and IEC 60068-2-27 (shock)

- **Protection Class**: IP20 for standard cabinet mounting

Functional Capabilities: Beyond Basic Processing

Advanced Control Capabilities

- **Multi-domain Control**: Simultaneous handling of continuous, batch, and discrete control strategies

- **Advanced Regulatory Control**: Sophisticated PID algorithms with adaptive tuning capabilities

- **Model Predictive Control (MPC)**: Native support for advanced control algorithms

- **Fuzzy Logic**: Built-in libraries for complex decision-making processes

- **Statistical Process Control**: Real-time SPC for quality monitoring and optimization

Communication & Networking

- **Integrated Interfaces**:

- Dual Ethernet ports (10/100/1000 Mbps) with switch functionality

- PROFINET IRT/RT with integrated switch

- PROFIBUS DP master/slave capability

- Modbus TCP/RTU master/slave support

- Serial RS-232/485 interfaces

- **Network Protocols**:

- OPC UA (Unified Architecture) for secure data exchange

- IEC 61850 for power systems integration

- SNMP for network management

- HTTP/HTTPS for web services

- NTP for time synchronization

- **Cybersecurity Features**:

- Integrated firewall with configurable security zones

- Role-based access control (RBAC)

- Audit logging and event recording

- Support for digital certificates and secure boot

Programming & Configuration Environment

- **Compliance Standards**: Full adherence to IEC 61131-3 programming standards

- **Supported Languages**:

- Function Block Diagram (FBD)

- Ladder Diagram (LD)

- Structured Text (ST)

- Instruction List (IL)

- Sequential Function Chart (SFC)

- **Engineering Tools**: Configuration via ABB's Control Builder PLUS engineering suite

- **Version Control**: Integrated support for change management and version tracking

- **Simulation Capabilities**: Full-featured simulation environment for offline testing

Application Domains: Where Performance Matters Most

Oil & Gas Industry

- **Upstream Applications**: Offshore platform control, wellhead management, pipeline SCADA

- **Midstream Operations**: Pump station control, compressor automation, custody transfer

- **Downstream Processing**: Refinery unit control, blending operations, tank farm management

- **Safety Systems**: Integration with ESD (Emergency Shutdown) and F&G (Fire & Gas) systems

Power Generation & Distribution

- **Conventional Power Plants**: Boiler control, turbine management, balance-of-plant automation

- **Renewable Energy**: Solar farm optimization, wind turbine control, hydroelectric plant automation

- **Grid Management**: Substation automation, feeder protection, load management

- **Combined Heat & Power (CHP)**: Integrated energy system optimization

Chemical & Petrochemical Processing

- **Continuous Processes**: Reactor control, distillation column optimization, heat exchanger networks

- **Batch Processing**: Recipe management, phase logic control, batch tracking and reporting

- **Safety Instrumented Systems**: SIL-rated safety loops for critical process protection

- **Environmental Compliance**: Emissions monitoring and control

Pharmaceutical & Life Sciences

- **GMP Compliance**: Full audit trail, electronic signatures, 21 CFR Part 11 compliance

- **Batch Documentation**: Automated batch record generation and management

- **Process Validation**: Support for validation protocols and documentation

- **Clean-in-Place (CIP)**: Automated cleaning sequence control and verification

Water & Wastewater Management

- **Treatment Plants**: Process control for biological treatment, clarification, filtration

- **Pump Station Control**: Intelligent pumping strategies for energy optimization

- **Distribution Networks**: Pressure zone management, leak detection, quality monitoring

- **SCADA Integration**: Wide-area monitoring and control systems

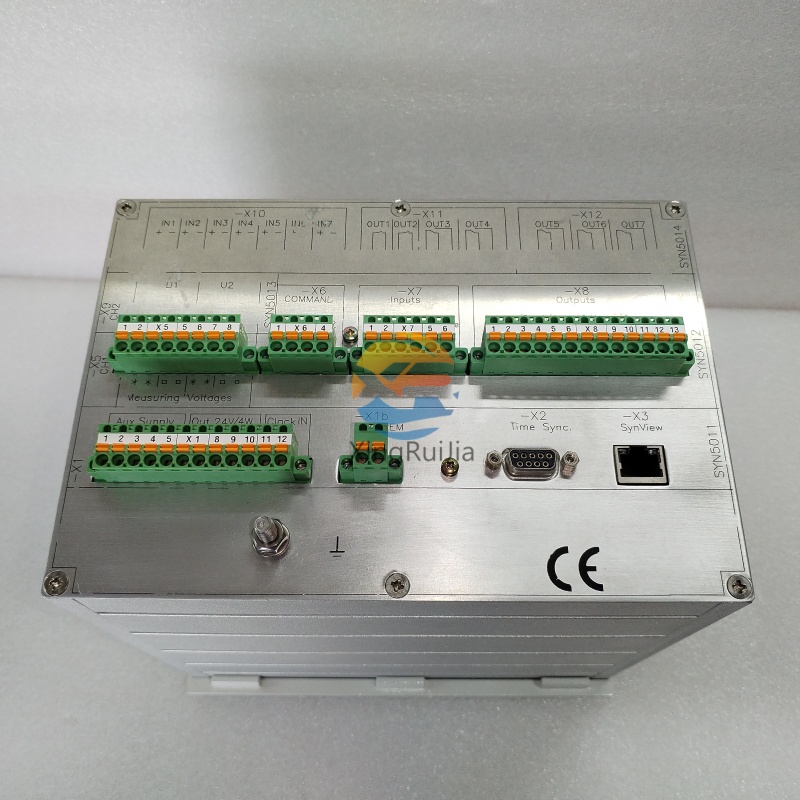

System Architecture & Integration

Hardware Integration

- **Backplane Compatibility**: Designed for ABB's S800 I/O series and other compatible I/O systems

- **Expansion Capabilities**: Support for up to 100 local and remote I/O drops

- **Hot Swappability**: Support for hot swapping of modules in redundant configurations

- **Mounting Options**: Standard 19" rack mounting or custom panel mounting

Software Ecosystem

- **Control Builder PLUS**: Primary engineering environment with unified database

- **Asset Optimization Tools**: Integration with ABB Ability™ Asset Vista condition monitoring

- **MES/ERP Connectivity**: Standard connectors for SAP, Oracle, and other enterprise systems

- **Historian Integration**: Direct interfaces to OSIsoft PI, AspenTech IP21, and other historians

- **HMI/SCADA Connectivity**: Native drivers for ABB's 800xA and other major SCADA platforms

Redundancy Configuration

- **CPU Redundancy**: 1:1 hot standby configuration with bumpless transfer

- **Power Supply Redundancy**: Support for N+1 power supply configurations

- **Network Redundancy**: Media redundancy protocols (MRP, PRP, HSR) support

- **I/O Redundancy**: Support for redundant I/O modules in critical applications

Installation & Commissioning Guidelines

Pre-installation Requirements

- **Environmental Conditions**: Ensure compliance with temperature, humidity, and cleanliness requirements

- **Power Quality**: Verify stable power supply within specified voltage ranges

- **Grounding**: Proper grounding according to ABB specifications and local electrical codes

- **Space Planning**: Adequate clearance for ventilation and maintenance access

Installation Procedure

1. **Rack Assembly**: Mount in designated slot following mechanical guidelines

2. **Power Connection**: Connect to redundant power supplies with proper polarity

3. **Network Wiring**: Implement structured cabling with proper segregation of signal types

4. **Grounding**: Ensure proper earth grounding for noise immunity

5. **Configuration Backup**: Load firmware and initial configuration before system startup

Commissioning Steps

- **System Power-Up**: Sequential startup following ABB recommended procedures

- **Diagnostic Verification**: Confirm all diagnostic indicators show normal operation

- **Redundancy Testing**: Verify proper operation of redundant components

- **Communication Validation**: Test all network connections and protocol configurations

- **Application Download**: Transfer control strategies and verify proper execution

Maintenance & Lifecycle Management

Preventive Maintenance Schedule

- **Daily/Weekly**: Visual inspection, temperature monitoring, error log review

- **Monthly**: Backup verification, firmware update checks, security audit log review

- **Quarterly**: Redundancy switchover testing, battery status check, cleaning of air filters

- **Annually**: Complete diagnostic check, firmware updates (if required), load testing

Troubleshooting Guide

- **LED Indicators**: Comprehensive status indication through multi-color LEDs

- **Diagnostic Tools**: Built-in web server with detailed diagnostic information

- **Remote Diagnostics**: Secure remote access for troubleshooting and support

- **Spare Parts Strategy**: Recommended spare parts inventory based on criticality

Firmware Management

- **Update Procedures**: Step-by-step firmware update process with rollback capability

- **Version Compatibility**: Matrix of compatible firmware versions with other system components

- **Security Patches**: Regular security updates addressing evolving cybersecurity threats

- **Documentation Updates**: Associated documentation revisions with firmware releases

Compliance & Certifications

Industry Standards Compliance

- **Electromagnetic Compatibility**: EN 61326, IEC 61326 (Industrial environments)

- **Safety Standards**: UL 508, CSA 22.2 No. 142, EN 61131-2

- **Marine Applications**: DNV-GL, ABS, LR, and other marine classification societies

- **Functional Safety**: IEC 61508, IEC 61511 (when used in safety applications)

- **Cybersecurity**: IEC 62443, NERC CIP (for applicable regions)

Regional Approvals

- **North America**: UL, cUL, FCC Part 15

- **Europe**: CE Marking, ATEX (for specific configurations)

- **International**: IEC, GOST-R, CCC (China)

Ordering Information & Technical Support

Part Number Breakdown

- **PPD539A102**: Base product identifier for AC 800PEC CPU module

- **3BHE039770R01**: Specific revision and configuration identifier

- **AC 800PEC**: Product series designation (Process Edge Controller)

Accessories & Required Components

- **Memory Cards**: Optional expansion memory modules

- **Battery Units**: Backup batteries for memory retention

- **Mounting Kits**: Additional mounting hardware for specific configurations

- **Communication Modules**: Additional protocol-specific communication interfaces

Support Services

- **Technical Documentation**: Available through ABB's MySupport portal

- **Software Updates**: Regular firmware and engineering tool updates

- **Training Programs**: Certified training courses for engineers and technicians

- **Global Support Network**: 24/7 technical support through ABB's worldwide service centers

- **Warranty**: Standard 24-month warranty with extended service options

Competitive Advantages & Value Proposition

Technological Differentiation

- **True Process Optimization**: Specifically designed for complex process control rather than adapted from machine control platforms

- **Cybersecurity by Design**: Integrated security features rather than add-on components

- **Future-Proof Architecture**: Support for emerging technologies like IIoT, edge computing, and cloud connectivity

Economic Benefits

- **Reduced Total Cost of Ownership**: Higher reliability reduces unplanned downtime

- **Energy Efficiency**: Optimized processing reduces overall system power consumption

- **Scalability**: Modular design allows for cost-effective system expansion

- **Interoperability**: Reduced integration costs through support for multiple standards

Sustainability Impact

- **Resource Optimization**: Advanced control algorithms minimize raw material and energy consumption

- **Extended Equipment Life**: Optimal process control reduces equipment stress and wear

- **Emissions Reduction**: Precise control helps minimize environmental impact

Migration Path & Future Development

Legacy System Migration

- **Upgrade Paths**: Defined migration strategies from previous generation AC 800M controllers

- **Conversion Tools**: Automated conversion utilities for existing control strategies

- **Training Transition**: Comprehensive training programs for engineers familiar with previous systems

Technology Roadmap

- **Continuous Development**: Regular feature enhancements through firmware updates

- **IIoT Integration**: Enhanced connectivity for Industrial Internet of Things applications

- **Cloud Integration**: Improved interfaces for cloud-based analytics and monitoring

- **Artificial Intelligence**: Support for AI/ML algorithms at the edge

Conclusion: The Intelligent Choice for Process Excellence

The

ABB PPD539A102 3BHE039770R01 AC 800PEC Central Processing Unit represents more than just a controller—it embodies a comprehensive solution for modern process automation challenges. By combining unparalleled processing power with industrial-grade reliability, cybersecurity, and flexibility, this CPU module provides the foundation for digital transformation in process industries.

Whether deployed in a conventional plant modernization project or as part of a greenfield digitalization initiative, this controller delivers the performance, safety, and future-readiness that today's competitive industrial environment demands. Its compliance with international standards, support for open protocols, and integration with ABB's broader automation ecosystem ensure that it will continue to deliver value throughout its operational lifecycle.

For organizations seeking to enhance operational efficiency, improve safety performance, and build a foundation for Industry 4.0 initiatives, the ABB AC 800PEC CPU stands as a proven, capable, and intelligent choice that bridges traditional automation with the digital future.

CUSTOMERS WHO PURCHASED THIS PRODUCT ALSO VIEWED THESE PRODUCTS:

Sweden

Sweden

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)